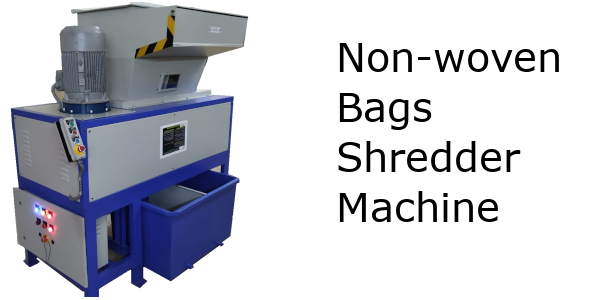

Non-woven bags are shredded using a dual shaft shredder machine from Raj Electricals. Non-woven bags are made of polypropylene (pp) and polypropylene is categorized as plastic. As plastic waste is hazardous non-woven bag recycling is necessary and one of the primary steps in recycling is shredding. Non-woven Bags shredder shreds non-woven bags to small sizes. Read More

Dual Shaft Shredder DS5007 from Raj Electricals is a heavy-duty shredder machine built with two shafts of blades which enables it to shred huge volumes of non-woven bags which includes non-woven cement bags, non-woven jumbo bags, non-woven cement sacks, etc.

Dual shaft shredder DS5007 is used to shred non-woven bags because of its low speed and also because it uses high torque technology to shred these non-woven bags. The capacity of DS5007 is approximately 200 kgs/hr. Another advantage is it enables auto-reverse during overload protection and prevents blade damage. We have five more models of dual shaft shredder apart from DS5007 and they are – DS1015, DS2002, DS3003, DS4005, DS7510, providing varying capacity output. Dual shaft shredder machine from Raj Electricals runs for 24 hours – continuous duty – no cooling required. Double Shaft Non-Woven Bags Shredder from Raj Electricals can also be used to shred plastic drums, hard disk drive shredder. This type of dual shaft shredder is also used to shred various other items, which include vials, ampoules, glucose bottles, syringes, catheters, saline bottle, saline tubes, blister packs, lami tubes, plastic jars, pet bottles, food waste, hospital waste, PVC blisters, papers, carton, fibre material, etc.

Salient features of Non-woven Bags Shredder Machine DS5007:

Kindly contact us for details of various models, prices and trial of Non-woven Bags Shredder Machine.

| Technical Specifications of Non-woven Bags Shredder | |

|---|---|

| Model | "DS5007" |

| Feed Width | 500 mm |

| Power Required | 7.5 hp / 5.6 kw |

| Machine Dimension (approx) | 1350 mm x W 900 mm X H 1850 mm | Shred Capacity |

| Shred Size | 25 x 60 (uneven) |

| 200 kgs/hr | |

| Duty Cycle | Continuous – non-stop running, no cooling required |

| Applications | Can shred HDPE and LDPE (Cement Bag/Non-woven Bag),paper, pet bottles, hospital waste, cartons, fibre material, syringes, vials, ampoules, saline bottles, catheters,glucose bottles, saline tubes, lami tubes, blister packs, PVC blisters,etc |